Maintaining Brake Systems

Brake failure is the most common cause for accidents involving semi trucks. The brake systems are the most vital and critical component on these 80,000 pound vehicles that can never be checked enough. Below are some tips to help assure you are taking the proper precautions on the road.

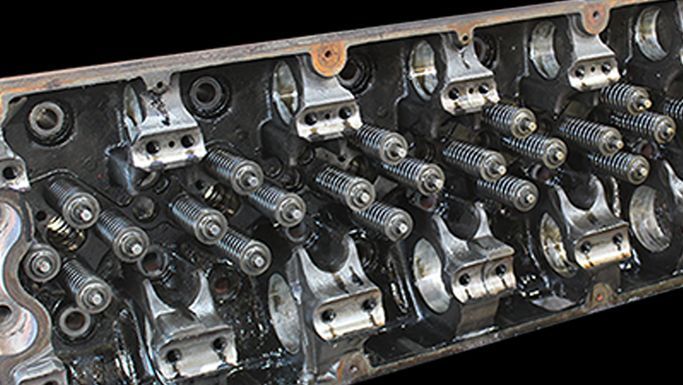

Replacing Brakes Regularly – The brake shoes on a truck are equipped with an indicator built into the pads that will warn you when it is time for a replacement. When you are replacing your pads, you should also replace springs, pins, and bushings. When the brake shoes are replaced, be sure to replace the drums as well. Drums are prone to wear, and they can begin to develop heat cracks.

Grease S Cams & Slack Adjusters – Trucks have 2 types of slack adjusters; manual or automatic. Slack Adjusters are what work to keep your brakes in alignment during use. The slack adjusters turn a shaft that then turns the S cam. The S cams responsibility is to push the brake shoe into the drum to stop the truck. Regardless the type of adjuster you have, it needs to be greased to work properly and efficiently, as well as the bushings in the S cams.

Check the Air System Pressure Gauge – The ideal pressure reading for your truck should be between 100-125 PSI. Checking the pressure gauge is very important in determining if you should service your brakes or stop driving the truck all together until the brakes are serviced or replaced. If the pressure gauge is reading anywhere between 60-100, you should have your brakes serviced. If your pressure gauge is reading under 60, stop driving the truck immediately until that brakes are serviced or replaced.

Check Linings and Hoses – Be sure that all linings and hoses are dry and free of lubricants or fluids. If you see any soaked lines or hoses, they should be replaced. Also make sure to look for any hoses that are worn or damaged, as they will need to be replaced as well.

One good rule of thumb is to check your brakes every time you get your oil changed. This will help you stay on top of services.

Contact us to learn about our inventory of brake parts.