When Should A Fuel Injector Be Replaced?

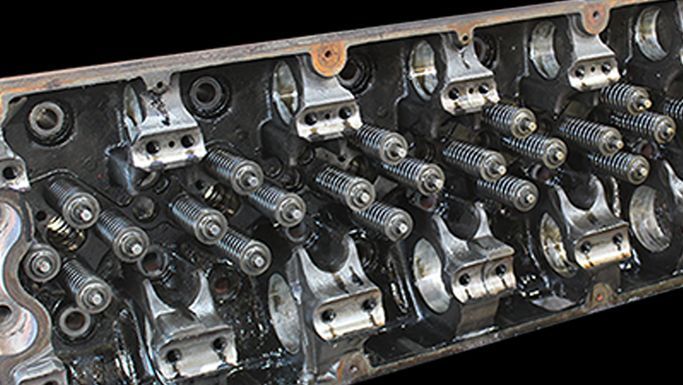

There is a huge difference between a diesel engine and a gasoline engine. One of the biggest differences is the fuel injection process. A gasoline engine mixes fuel with air, and then it is compressed by the pistons, and ignited by the spark plugs. Diesel engines compress the air first, and then the fuel is injected directly into the cylinder. Compressing air first eliminates the need for spark plugs. The fuel is injected in a mist as its easier to ignite than a solid stream of fuel would be. This helps it burn more evenly and efficiently. Deposits can build up overtime and become clogged, which will ultimately effect the injectors performance. There are plenty of warning signs that help give away when a fuel injector

may be clogged.

There is a huge difference between a diesel engine and a gasoline engine. One of the biggest differences is the fuel injection process. A gasoline engine mixes fuel with air, and then it is compressed by the pistons, and ignited by the spark plugs. Diesel engines compress the air first, and then the fuel is injected directly into the cylinder. Compressing air first eliminates the need for spark plugs. The fuel is injected in a mist as its easier to ignite than a solid stream of fuel would be. This helps it burn more evenly and efficiently. Deposits can build up overtime and become clogged, which will ultimately effect the injectors performance. There are plenty of warning signs that help give away when a fuel injector

may be clogged.

Symptoms Of Clogged Fuel Injectors

Some symptoms of a clogged fuel injector include:

- Hard Starting / Starting Issues

- Rough Idle

- Increase In Fuel Consumption

- Throttle Hesitation

- Poor Performance

- Air or water in fuel system

- Damage from other internal engine failures

- Age & wear

- Clogging

- Cracked

- Broken seals/Leaking

- Internal components failure

If you are experiencing any of the issues above, it may be time to clean or replace your fuel injectors.

Causes of Injector Failures

- Air or water in the fuel system

- Secondary damage as a result of internal engine failure

- Age and wear

- Internal injector components failing

- Clogging

- Busted seals and leaking

- Cracking

Should I Repair or Replace? You should decide whether or not you want to repair or replace your injectors. The most common smaller damage that is fairly easy to repair is damaged o-rings. Any more substantial and it might be best to replace them. If you are experiencing issues with your engine, you should contact a mechanic before the issue progresses.