Symptoms of Bad or Failing Oil Cooler

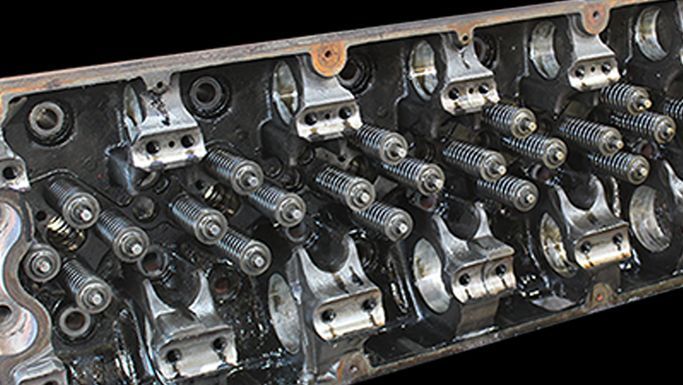

How does your oil cooler work?

Your oil cooler does exactly what it sounds like, it cools down the oil running through your engine. For proper performance, your oil cooler must be in working order no matter the driving conditions. The cooled oil is used to cool down multiple components such as the crankshaft, bearings, camshaft, rods, and pistons. This cooling can impact overall performance. It helps keep the engine running smoothly, during hot weather and on long-haul trips, which is typically when things tend to breakdown, overheat, or have problems. Although most drivers never consider oil cooler maintenance, keeping them in working order by changing the engine coolant and oil at the recommended intervals will help reduce wear and tear on the engine. Like all other working components, they can and will wear out.

Another thing to keep in mind is that the oil cooler should be replaced after any engine failure. The best way to protect a repaired or rebuilt engine is to install a new oil cooler to prevent any potential contamination. On startup, the repaired engine will have higher oil pressure that can dislodge trapped debris in the oil cooler and force it into the bearings of the new engine. This can cause premature wear or sometimes immediate failure.

Types of Oil Coolers:

- Filter Mounted

- In-Tank

- Remote Mounted

- Engine Mounted – This type of cooler is most commonly used on diesel engines.

Although they all perform the same job, they vary in location and process.

Signs of Engine Cooler Failure

- Decreased Performance

- Black Smoke

- Oil in Cooling System

- Leaking Oil

- Rusting Oil Cooler

The oil cooler is an important part of your engine’s operation. If you are experiencing any of the issues above, replacing your oil cooler will help improve your engine cooling and will help to extend the life of your engine for miles to come. When looking for replacement parts or any replacement drivetrain components, please reach out to River City Truck Parts and give us a chance to quote your next part purchase.